new-technology refined bleached deodorized oil press equipment

RBD (Refined Bleached Deodorized) Coconut Oil Market

Feb 15, 2021· 5.2 RBD (Refined Bleached Deodorized) Coconut Oil Market Size Forecast by Type 5.2.1 Rigid (PET 5.2.2 HDPE 5.2.3 Tin Plate) 5.2.4 Semi Rigid (Tetra Pak) 5.2.5 Flexible (Flexibags) 5.3 Market Attractiveness Analysis by Type Chapter 6 Global RBD (Refined Bleached Deodorized) Coconut Oil Market Analysis and Forecast by Applications 6.1

RBD (Refined Bleached Deodorized) Coconut Oil Market

Besides, manufacturing of RBD (refined bleached deodorized) coconut oil is a matter of prestige and valuation for vendors. This factor, coupled with the evident benefits of RBD coconut oil over virgin oil, has spun the growth game of the market. Fats present in RBD coconut oil are researched to fight inflammation in the body.

Palm Oil Refinery Plant|Refined Bleached and Deodorized

The process of creating a refined bleached and deodorized palm oil requires two different but relative techniques— palm oil mill and palm kernel recovery. Palm oil mill: The first technique uses a horizontal sterilizer to steam the fresh fruits to prevent unnecessary oil acidification.

Optimization of Bleaching Process AOCS

Bleaching is the physical and chemical interaction of an oil or fat with bleaching earth to improve its quality. One definition of quality is “to reach a level of excellence.” However, with respect to oil specifications, it is quite variable and depends on the product and market we are dealing with. For example, for deep-frying oils, it is very important that phosphorus (P) be as low as possible anpalm oil bleaching machine, palm oil bleaching machine

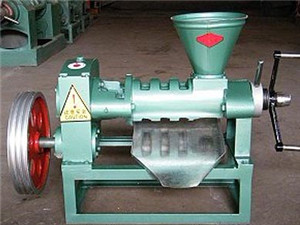

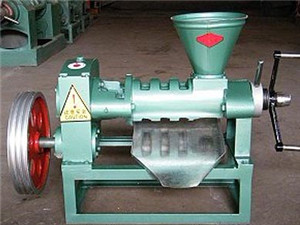

High quality small capacity oil bleaching equipment,edible palm oil refined bleached machinery for vegetable cooking Oil Zhengzhou Thrive Trade Co., Ltd. refined bleached deodorized palm oil machine for sunflower oil double refined machine Our small oil press machine adopt new type big modulus helical gear transmission, can boost

Understanding the various types of oil processing Insta

Oct 18, 2018· The highest level of oil processing is known as refined, bleached, and deodorized (RBD). This is generally referred to as food grade oil. The oil is degummed, neutralized, deodorized, and bleached. These processes remove gums (phospholipids), odors (those inherent to the oilseed, not necessarily bad), and colors (to make the oil appear more

Bleaching Process, Oil Bleaching Process, Crude Oil

Bleaching Process is the third step in vegetable oil refining which commences after complete of effective neutralization process. Bleacher Pressure Vessel is used to carry out the Bleaching Process. A Bleacher is careful designed equipment based on design parameters to ensure perfect bleach-ability of the crude oil. The process has its own

Deodorization an edible oil refinery small oil refining machine

Deodorization of refined and bleached oil is carried out under vacuum and at an absolute pressure of 1–6 mm of mercury in the United States, depending on the type of vacuum system on the deodorizer. Modern deodorizers in Europe and the United States are operated at 2–3 mm of mercury or even lower vacuum (1 mm) via a special ejector design to be discussed in Chapter

Deodorization AOCS

The quality of Wesson’s deodorized oil was for many decades a standard for edible oils throughout the world [1]. Over the years, deodorization gradually evolved from a ‘simple’ process to remove off-flavors to a crucial unit operation with a big impact on the refined oil quality.

About Mt. Makiling International Oil

To animate our vision to be the leading producer of refined, bleached, deodorized oil and other oil-based quality products, the company is investing heavily on new equipment and facilities. In response to the growing demand for oils intended for food processing, the company has ventured into oil modification which include hydrogenation

Palm Oil Refinery Plant|Refined Bleached and Deodorized

Next, the oil is heated, dried, and then de-aerated while absorbing its color through continuous agitation. And lastly, the oil is again heated by a deodorizing oil. Afterwards, the oil is cooled at storage temperature before it goes to the polishing filters. And that is how a refined bleached and deodorized palm oil is created.

Deodorization Process, Oil Deodorization Oil Refinery

Deodorization Process is the forth step in vegetable oil refining which commences after finishing the bleaching. Deodorization holds a big impact on the refined oil quality and is often considered as the heart of the entire edible oil refining method.

palm oil bleaching machine, palm oil bleaching machine

High quality small capacity oil bleaching equipment,edible palm oil refined bleached machinery for vegetable cooking Oil Zhengzhou Thrive Trade Co., Ltd. refined bleached deodorized palm oil machine for sunflower oil double refined machine Our small oil press machine adopt new type big modulus helical gear transmission, can boost

Soybean Oil Refinery Plant Manufacturer & Exporter Goyum

Deodorisation. The Bleached oil is further heated using heat recovery economizers and raised the temperature to 120°C and fed to de aerator where all kinds of air contamination will be removed and further heated with, outgoing deodorized oil and further heated with high temperature heater to raise the temperature upto 240 to 250°C with the help of either thermic

Optimization of Bleaching Process AOCS

Bleaching temperature vs. color comparison of refined bleached (RB) (upper) vs. refined bleached & deodorized (RBD) (lower) corn oils. Temperature. Oil bleaching temperatures typically range from 90–125°C (195–257°F). Temperature affects oil

Deodorization an edible oil refinery small oil refining machine

Deodorization of refined and bleached oil is carried out under vacuum and at an absolute pressure of 1–6 mm of mercury in the United States, depending on the type of vacuum system on the deodorizer. Modern deodorizers in Europe and the United States are operated at 2–3 mm of mercury or even lower vacuum (1 mm) via a special ejector design to be discussed in Chapter

Deodorization AOCS

The quality of Wesson’s deodorized oil was for many decades a standard for edible oils throughout the world [1]. Over the years, deodorization gradually evolved from a ‘simple’ process to remove off-flavors to a crucial unit operation with a big impact on the refined oil quality.

Bleaching Process, Oil Bleaching Process, Crude Oil

Bleaching Process is the third step in vegetable oil refining which commences after complete of effective neutralization process. Bleacher Pressure Vessel is used to carry out the Bleaching Process. A Bleacher is careful designed equipment based on design parameters to ensure perfect bleach-ability of the crude oil. The process has its own

latest technology physical refining of palm oil equipment

Professional latest technology physical refining of palm oil equipment is used to Corn Flour Processing Plant can reach the capacity 200-1500kg/h,high efficiency and excellent effect, it is the most advanced Shandong Oil Processing Machinery Co.,Ltd. in china.

Innovative Palm Oil Solutions Alfa Laval

Innovative, sustainable processing solutions for the palm oil extraction machine industry Solutions that add value In response to challenges facing players in the competitive palm oil milling, refining and fats modification industry, Alfa Laval has developed a range of innovative solutions that offer sustainable alternatives to traditional technology.

RBD (Refined Bleached Deodorized) Coconut Oil Market 2027

Besides, manufacturing of RBD (refined bleached deodorized) coconut oil is a matter of prestige and valuation for vendors. This factor, coupled with the evident benefits of RBD coconut oil over virgin oil, has spun the growth game of the market. Fats present in RBD coconut oil are researched to fight inflammation in the body.

Cooking Oil Refining Machines Solution and Technology

The oil refining process, a series of advanced technology and equipment are used, such as super wet deguming, bleaching earth automatic metering, negative pressure decoloring, high vacuum steam jet deodorization, deacidification, winterization dewaxing etc.With advanced technology, superior equipment, full-automatic control and excellent

Low cost Palm oil refining process machinery price for

Jan 28, 2021· New palm oil fractionation technology adopts advanced crystallization equipment, filtration & pressing technology, and accurate temperature auto-control software, which keep paces with the word. The new technology is especially applicable for the palm oil fractionation, which can get different melting-point fractionations, including 14℃, 18

HollyFrontier Cheyenne Renewable Diesel: Fluor Project

HollyFrontier Cheyenne Renewable Diesel Project. Fluor was selected to modify HollyFrontier's Cheyenne Refinery to process refined, bleached and deodorized soybean oil for renewable diesel production. Fluor executed front end engineering and design (FEED), detailed engineering and procurement services on the project.

Deodorization Process, Oil Deodorization Oil Refinery

Deodorization Process is the forth step in vegetable oil refining which commences after finishing the bleaching. Deodorization holds a big impact on the refined oil quality and is often considered as the heart of the entire edible oil refining method.

Palm Oil Refinery Plant|Refined Bleached and Deodorized

Next, the oil is heated, dried, and then de-aerated while absorbing its color through continuous agitation. And lastly, the oil is again heated by a deodorizing oil. Afterwards, the oil is cooled at storage temperature before it goes to the polishing filters. And that is how a refined bleached and deodorized palm oil is created.

RBD (Refined Bleached Deodorized) Coconut Oil Market 2027

Besides, manufacturing of RBD (refined bleached deodorized) coconut oil is a matter of prestige and valuation for vendors. This factor, coupled with the evident benefits of RBD coconut oil over virgin oil, has spun the growth game of the market. Fats present in RBD coconut oil are researched to fight inflammation in the body.

latest technology physical refining of palm oil equipment

Professional latest technology physical refining of palm oil equipment is used to Corn Flour Processing Plant can reach the capacity 200-1500kg/h,high efficiency and excellent effect, it is the most advanced Shandong Oil Processing Machinery Co.,Ltd. in china.

Optimization of Bleaching Process AOCS

Bleaching temperature vs. color comparison of refined bleached (RB) (upper) vs. refined bleached & deodorized (RBD) (lower) corn oils. Temperature. Oil bleaching temperatures typically range from 90–125°C (195–257°F). Temperature affects oil

Deodorization AOCS

The quality of Wesson’s deodorized oil was for many decades a standard for edible oils throughout the world [1]. Over the years, deodorization gradually evolved from a ‘simple’ process to remove off-flavors to a crucial unit operation with a big impact on the refined oil quality.

Cooking Oil Refining Machines Solution and Technology

The oil refining process, a series of advanced technology and equipment are used, such as super wet deguming, bleaching earth automatic metering, negative pressure decoloring, high vacuum steam jet deodorization, deacidification, winterization dewaxing etc.With advanced technology, superior equipment, full-automatic control and excellent

palm oil bleaching machine, palm oil bleaching machine

High quality small capacity oil bleaching equipment,edible palm oil refined bleached machinery for vegetable cooking Oil Zhengzhou Thrive Trade Co., Ltd. refined bleached deodorized palm oil machine for sunflower oil double refined machine Our small oil press machine adopt new type big modulus helical gear transmission, can boost

Soybean Oil Refinery Plant Manufacturer & Exporter Goyum

Deodorisation. The Bleached oil is further heated using heat recovery economizers and raised the temperature to 120°C and fed to de aerator where all kinds of air contamination will be removed and further heated with, outgoing deodorized oil and further heated with high temperature heater to raise the temperature upto 240 to 250°C with the help of either thermic

Innovative Palm Oil Solutions Alfa Laval

Innovative, sustainable processing solutions for the palm oil extraction machine industry Solutions that add value In response to challenges facing players in the competitive palm oil milling, refining and fats modification industry, Alfa Laval has developed a range of innovative solutions that offer sustainable alternatives to traditional technology.

Bleaching Process, Oil Bleaching Process, Crude Oil

Bleaching Process is the third step in vegetable oil refining which commences after complete of effective neutralization process. Bleacher Pressure Vessel is used to carry out the Bleaching Process. A Bleacher is careful designed equipment based on design parameters to ensure perfect bleach-ability of the crude oil. The process has its own

CFR Code of Federal Regulations Title 21 Food and Drug

Jan 06, 2022· (c) Low erucic acid rapeseed oil. (1) Low erucic acid rapeseed oil, also known as canola oil, is the fully refined, bleached, and deodorized edible oil obtained from certain varieties of Brassica Napus or B. Campestris of the family Cruciferae. The plant varieties are those producing oil-bearing seeds with a low erucic acid content.

Understanding the various types of oil processing Insta Pro

Oct 18, 2018· The highest level of oil processing is known as refined, bleached, and deodorized (RBD). This is generally referred to as food grade oil. The oil is degummed, neutralized, deodorized, and bleached. These processes remove gums (phospholipids), odors (those inherent to the oilseed, not necessarily bad), and colors (to make the oil appear more

Deodorization an edible oil refinery small oil refining machine

Deodorization of refined and bleached oil is carried out under vacuum and at an absolute pressure of 1–6 mm of mercury in the United States, depending on the type of vacuum system on the deodorizer. Modern deodorizers in Europe and the United States are operated at 2–3 mm of mercury or even lower vacuum (1 mm) via a special ejector design to be discussed in Chapter

Post navigation