clarification for the crude palm oil milling process

What is the process of palm oil clarification?_Palm Oil

Nov 16, 2018· Crude palm oil clarification can extract crude palm oil from sludge. The obtained crude palm oil purity can reach up 90%. The extraction oil contains 45%-55% moisture, sludge and other impurities. Purification: crude palm oil purification can improve oil purity and remove impurity successfully.

crude palm oil clarification system palmoilmillplant

Clarification Process in Palm Oil Production Use of a Vibrating Screen To begin with, the crude oil carries with it all types of matter. Some of the solid materials are: fibers from the palm fruit, dirt, and fragments. It is important to remove from the mixture the large particles first. There is no way that the solids can be allowed through.

The Operation Details About Clarification Of Palm Oil

Clarified oil flow into storage oil tank from discharge hole of palm oil clarification tank, after Disc-type separator remove moisture in the oil, then though Plate heat exchanger heating to 105℃, remove residual moisture out from oil by Vacuum drier. 5. Vacuum degree of vacuum drying is achieved by Vacuum pump.

Palm oil mill process flow diagram introduction_Palm Oil

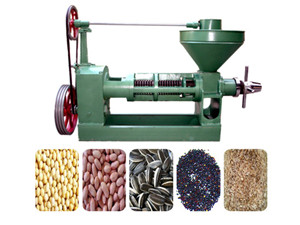

Apr 11, 2019· Palm fruit digesting and pressing machine Transport the palm fruits to the digester to mixed and cooked again to separate the palm pulp and nut, then use double screw hydraulic palm oil presser to get crude palm oil, which improved the production efficiency greatly. 5.Oil clarification station Crude palm oil clarification machine

Palm Oil Clarification Station Palm Oil Mill Machine

The equipment list of clarification station: 1.1st Stage Precleaner c/w Pump 2.Vertical Continuous Setting Tank 3.Pure Oil Tank 4.Pure Oil Pump 5.Vacuum Oil Dryer c/w Float Tank and Pump 6.Sludge Oil Tank 7.2nd Stage Precleaner c/w Pump 8.SS.Decanter Feed Tank 9.Separator Feed Tank 10.Decanter Hot Water Tank 11.3PH Decanter 12.3PH Decanter

SEPARATION TEHCNIQUE OF CRUDE PALM OIL AT

The purpose of clarification is to separate the oil from its entrained impurities such as water, cell debris, fibrous material and non oily solid (N.O.S). In this study, optimum parameter such as temperature, effect of impeller, residence time and separation technique of crude palm oil is at clarification stage is determined.

Palm Palm Oil Mill Process for Starting Palm Oil

The process of palm oil extraction is very different from the processing of other seeds. Gnerally, palm oil mill includes 6 processes: fruits reciving, cooking/sterilizing, threshing, digesting, oil pressing, crude oil clarification, refining and fractionation, and pal kernel recovery. Palm Oil Mill Process Machines

Palm oil mill process pdf Australia guidelines User Examples

Feb 07, 2022· 1.Palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge. 2.Palm oil mil process of sterilization: the use of high temperature to cook soft fruit bunches and sterilization, easy to separate fruit bunches, soft fruit, increasing the humidity

Palm Oil Mill Machine_palm oil processing machine,edible

Air separation and washing systems separate palm kernels and shells. Shells enters boiler system as fuel, and palm kernels are storage after drying.

3. PALM OIL PROCESSING

from palm oil extraction, and will often be carried out in mills that process other oilseeds (such as groundnuts, rapeseed, cottonseed, shea nuts or copra). The stages in this process comprise grinding the kernels into small particles, heating (cooking),

What is the process of palm oil clarification?_Palm Oil

Nov 16, 2018· The separated palm oil enters into circulating tank, and circulating pump sends it into oil clarification tank. The separated waste oil enters into slag pit discharge, and the upper oil is recovered into circulation oil tank. The crude palm oil clarification machine is the key equipment in palm oil mill process, especially in large scale palm

Clarification Process in Palm Oil Htoilmachine

The separated waste oil enters into slag pit discharge, and the upper oil is recovered into circulation oil tank. In complete palm oil productin plant, clarification is the process that ensures removal of all impurities from the crude oil.

Palm oil milling process SlideShare

Oct 13, 2015· Oil from the top is skimmed off and purified in the centrifuge prior to drying in vacuum dryer. The final crude palm oil is then cooled and stored. The lower layer from the clarification tank is sent to the centrifugal separator where the remaining oil is recovered. The oil is dried in vacuum dryers, cooled and sent to storage tanks. 8.

CRUDE PALM OIL CLARIFICATION BY CYCLO-SEPARATOR

n the clarification of crude palm oil in the mill, the crude slurry is held for 4 to 7 hr in a vertical clarifier to allow the oil to rise above the sludge. Hot water is added and the temperature maintained at 95oC to reduce the viscosity of the slurry to enhance the rising of the oil. However, these conditions also promote

Palm Oil Mill Machine_palm oil processing machine,edible

8.Palm oil mil process of clarification: Machine-pressed crude oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. The oil and the sludge taken out separated (by 90% pure oil) is taken out

Palm Oil Clarification Station Palm Oil Mill Machines

Purification: crude palm oil purification can improve oil purity and remove impurity successfully. Drying: Continuous Vacuum drier pumps water from crude palm oil. Palm oil moisture can reduces to as low as 0.1%. Continuous clarification tank clear lake containing oil enters into the oil tank, pump into centrifuge separation.

Crude Palm Oil Production Process_palm oil processing

Crude Palm Oil Mill Process Introduction: 1.Weighing Palm fruit into the factory after truck weighing, ease of production costing and after the settlement. 2.Loading ramp FFB after a ramp sieved to remove impurities into the transport machinery delivery to sterilization tank. 3.Sterilization The use of high temperatures to cook soft fruit bunches and sterilization (145 ℃

Palm oil mill process pdf Australia guidelines User Examples

Feb 07, 2022· 1.Palm oil mil process of bunch reception: as palm fruit unloading, cleaning, storage platform during palm oil mill processing, all hydraulic segmented discharge. 2.Palm oil mil process of sterilization: the use of high temperature to cook soft fruit bunches and sterilization, easy to separate fruit bunches, soft fruit, increasing the humidity

Process Lines for Crude Palm Oil Production

The crude oil process with 3-phase decanters does not need vertical clarifiers and sludge tanks. The pressed and de-sanded palm oil in this process is sent directly to the topd 3-phase decanter. The main advantage is to be seen in a much shorter process time and lower oil losses. The risk of oxidation of the crude oil is also less significant

Palm Oil AOCS

A palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. The capacity of mills varies between 60-100 tons FFB/h. A typical mill has many operation units as shown in Figure 2. This comprises sterilization, stripping, digestion and pressing, clarification, purification, drying and storage.

Environmentally Friendly Palm Oil Mills Palm Oil Mill

Managing Environmentally Friendly Palm Oil Mills. Asian Agri manages 22 mills to produce more than 1.1 million metric tons of palm oil is extracted CPO ( Crude Palm Oil ). The extraction process begins with the transportation of ripe Fresh Fruit Bunches (FFB) harvested from plantations to the mills. FFBs are then sterilized using steam for half

Palm Oil Mill Mecpro

A palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. The capacity of mills varies between 2.5 150 MT FFB/hr. A typical mill has many operational units as shown in Figure 2. This comprises of sterilization, stripping, digestion and pressing, clarification, purification, drying and storage.

Clarification and Drying of Oil VIRIDIS Engineering Sdn Bhd

Purification. Purification is a final process during which fine suspended solids are separated and removed from crude oil. Raw crude oil from the settling tank (top oil) is combined with recovered oil from the treatment of the settling tank underflow. This results in a total crude-oil production of about 163 kg per ton of FFB being processed.

Palm Oil Mill Effluent Wastewater Treatment Plant

Palm Oil Mill Effluent (POME) is the wastewater discharged from the sterilization process, crude oil clarification process and cracked mixture separation process. POME produce huge amount of methane gas from its anaerobic process and has 21 times Global Warming Potential (GWP) compared to other gases.

What is the process of palm oil clarification?_Palm Oil

Nov 16, 2018· The separated waste oil enters into slag pit discharge, and the upper oil is recovered into circulation oil tank. The crude palm oil clarification machine is the key equipment in palm oil mill process, especially in large scale palm oil mill,Crude palm oil clarification machine can ensure us obtained the pure crude palm oil.

What is the process of palm oil clarification?_Palm Oil

Nov 16, 2018· The separated palm oil enters into circulating tank, and circulating pump sends it into oil clarification tank. The separated waste oil enters into slag pit discharge, and the upper oil is recovered into circulation oil tank. The crude palm oil clarification machine is the key equipment in palm oil mill process, especially in large scale palm

crude palm oil clarification system palmoilmillplant

Palm oil processing project is a great business to invest in, which has very large market demand and profit space! Clarification Station of Palm Oil Mill. In complete palm oil productin plant, clarification is the process that ensures removal of all impurities from the crude oil.

The Operation Details About Clarification Of Palm Oil

1. After removing the fiber and oil residue by Screening filter, palm crude oil flow into Passivating oil tank. 2. The passivating oil tank will be inlet indirect steam and directly steam, after passivation treatment palm oil and water mixture will be pumped to High level tank by Chemical centrifugal pump, then flow into Clarifying tank stably.

Clarification Process in Palm Oil Htoilmachine

The separated waste oil enters into slag pit discharge, and the upper oil is recovered into circulation oil tank. In complete palm oil productin plant, clarification is the process that ensures removal of all impurities from the crude oil.

Palm Oil Clarification Station Palm Oil Mill Machine

Clarification station can extract crude palm oil from sludge. The obtained crude palm oil purity can reach up 90%. The extraction oil contains 45%-55% moisture, sludge and other impurities. Purification: crude palm oil purification can improve oil purity and remove impurity successfully. Drying: Continuous Vacuum drier pumps water from crude

Crude Palm Oil Mill Process Wix

Mar 11, 2018· A palm oil mill produces crude palm oil and kernels as primary products and biomass as secondary product. A typical mill has many operational units as shown in Figure 2. This comprises of sterilization, stripping, digestion

Palm oil mill process flow diagram introduction_Palm Oil

Apr 11, 2019· 5.Oil clarification station. Crude palm oil clarification machine. Machine-pressed crude palm oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment.

SEPARATION TEHCNIQUE OF CRUDE PALM OIL AT

2.4.3.1 Clarification of Wet process Crude Oil 2.4.3.2 Clarification of Centrifuge Crude Oil 2.4.3.3 Factor Affecting Settling 2.4.4 Clarification Tank Simulation ol The most important for oil palm mill is to maximize oil recovery to fulfill the demand. Global consumption of major oils and fats has been increasing over the last few

Process Lines for Crude Palm Oil Production

The crude oil process with 3-phase decanters does not need vertical clarifiers and sludge tanks. The pressed and de-sanded palm oil in this process is sent directly to the topd 3-phase decanter. The main advantage is to be seen in a much shorter process time and lower oil losses. The risk of oxidation of the crude oil is also less significant

What’s The Operation Of Palm Oil Processing Clarification

1. After removing the fiber and oil residue by Screening filter, palm crude oil flow into passivating oil tank. 2. The passivating oil tank will be inlet indirect steam and directly steam, after passivation treatment palm oil and water mixture will be pumped to High level tank by Chemical centrifugal pump, then flow into Clarifying tank stably.

3. PALM OIL PROCESSING

Therefore rigid process control during oil clarification need not be prescribed or incorporated in the design. The free fatty acids and the trace tocopherols contained in the crude palm oil after natural fermentation also have a laxative effect, which is desirable for African consumers for whom synthetic substitutes are a luxury.

Highly Efficient Palm Oil Milling Process for Palm Oil Mill

Mar 30, 2018· The palm oil milling process in palm oil mill comprises of grinding the palm kernels into small particles, heating (or cooking), and extracting the oil using an oilseed expeller or petroleum-derived solvent. The oil then requires clarification in a

Palm oil milling process SlideShare

Oct 13, 2015· Oil from the top is skimmed off and purified in the centrifuge prior to drying in vacuum dryer. The final crude palm oil is then cooled and stored. The lower layer from the clarification tank is sent to the centrifugal separator where the remaining oil is recovered. The oil is dried in vacuum dryers, cooled and sent to storage tanks. 8.

Post navigation