how to get permission for construct a crude oil refining plant

Oil Refinery Permits Environmental Integrity Project

10 Tar sands are also sometimes called “oil sands” (r eflecting the desire of developers to promote a more benign-sounding name), “extra-heavy crude,” or “heavy crude,” and consist of about 85% sand, clay, and silt; 5% water; and 10% crude bitumen (the “tar” th at can be converted to oil). Ann Bordetsky, et al .,

Crude Oil Refining Plant Process

Crude Oil Refining. We have extensive experience in the design and manufacture of refining equipment and the construction and operation of Crude Oil Refineries. PPE can build a Modular Refinery in our shops and it can be easily shipped to your location anywhere in the world. PPE can provide feasibility studies, site selection, soil tests needed

How to Start a Private Mini Crude Oil Refinery Business in

Please note that all mini crude oil refineries in Nigeria are mandated to obtain the appropriate certification, license and permits before they can legally operate in Nigeria and of course in most countries of the world. 12. Get the Necessary Legal Documents You Need to Operate

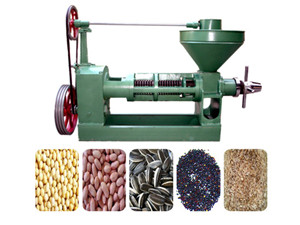

Crude Oil Refinery Plant/Equipment, Oil Refining Machine

Mar 02, 2017· The specific information of continuous waste oil refining plant has three models: BZL-25, and ITS daily capacitY are 25t/d. The continuous crude oil refinery machine can be operated under the condition of normal pressure. The design of continuous oil refinery plants is based on the batch machines, so the major operating flows are same.

Refining crude oil the refining process U.S. Energy

Petroleum refineries change crude oil into petroleum products for use as fuels for transportation, heating, paving roads, and generating electricity and as feedstocksfor making chemicals. Refining breaks crude oil down into its various components, which are then selectively reconfigured into new products. Petroleum refineries are complexand expensive industrial facilities. All refineriesOil Refinery Plant|Customized Edible Oil Refining Process

Referring to oil refining, the character of impurities contained in crude oil, and the purpose of refined oil must be concerned. 10-20ton per day will customize the oil refinery process and solution for each of customer depending on their specific situation and needs. So called “refinery”, generally refers to deacidificationprocess.

Estimated Cost of Building a Crude Oil Refinery in 2022

Today, national and state legislation mandates refineries to meet stringent air and water cleanliness standards. In fact, oil companies in the U.S. believe obtaining a permit to build a modern refinery to be so difficult and costly that no new refineries were built (though many have been expanded) in the U.S. from 1976 until 2014, when the small Dakota Prairie Refinery in NorOIL REFINERY PROCESSES

• Crude oil distillation is more complicated than product distillation, in part because crude oils contain water, salts, and suspended solids. • Step 1 in the refining process is to remove these contaminants so as to reduce corrosion, plugging, and fouling of equipment and to prevent poisoning catalysts in processing units.

How does a crude edible oil refinery plant work?_Tech

A crude edible oil refinery plant has five steps to refine the crude vegetable oil: Degumming, Deacidification, Decolorization, Deodorization and dewaxing or fractionation. But different edible oil refinery plant has different working process. There are three types of edible oil refinery plant: 1-20tpd batch type edible oil refinery plant, 10

petroleum refining Refinery plant and facilities

petroleum refining petroleum refining Refinery plant and facilities: Each petroleum refinery is uniquely configured to process a specific raw material into a desired slate of products. In order to determine which configuration is most economical, engineers and planners survey the local market for petroleum products and assess the available raw materials.

Oil Refinery Permits Environmental Integrity Project

10 Tar sands are also sometimes called “oil sands” (r eflecting the desire of developers to promote a more benign-sounding name), “extra-heavy crude,” or “heavy crude,” and consist of about 85% sand, clay, and silt; 5% water; and 10% crude bitumen (the “tar” th at can be converted to oil). Ann Bordetsky, et al .,

How to Start a Private Mini Crude Oil Refinery Business in

The oil and gas industry that mini crude oil refinery business is a part of will continue to blossom because people will always go to petrol stations to fuel their vehicles, purchase kerosene and cooking gas et al and all these are products from mini crude oil

Estimated Cost of Building a Crude Oil Refinery in 2022

Oil refining has long moved on from simple crude distillation and now does include an incredibly integrated complex upgrading & treating units. These complex configurations will cost more and affect the estimated cost of building a new refinery. 4. Capacity . Refining capacity refers to the amount of oil a plant can refine.

Refining crude oil the refining process U.S. Energy

Sep 23, 2020· How crude oil is refined into petroleum products. Petroleum refineries change crude oil into petroleum products for use as fuels for transportation, heating, paving roads, and generating electricity and as feedstocks for making chemicals.. Refining breaks crude oil down into its various components, which are then selectively reconfigured into new products.

The process of crude oil refining EME 801: Energy

PRESENTER: For crude oil to be used effectively by modern industry, it has to be separated into its component parts and have impurities like sulfur removed. The most common method of refining crude is the process of fractional distillation. This involves heating crude oil to about 350 degrees Celsius, to turn it into a mixture of gases.

Refining crude oil inputs and outputs U.S. Energy

Oct 15, 2021· The average processing gain at U.S. refineries was about 6.3% in 2020. In 2020, U.S. refineries produced an average of about 45 gallons of refined products for every 42-gallon barrel of crude oil they refined. Pie chart with 5 slices. Chart graphic. Bar chart with 11 bars.

AN INTRODUCTION TO PETROLEUM REFINING AND THE

Assessing the refining value of a crude oil requires a full description of the crude oil and its components, involving scores of properties. However, two properties are especially useful for quickly classifying and comparing crude oils: API gravity (a measure of density) and sulfur content. 3.2.1 API Gravity (Density)

petroleum refining Refinery plant and facilities

petroleum refining petroleum refining Refinery plant and facilities: Each petroleum refinery is uniquely configured to process a specific raw material into a desired slate of products. In order to determine which configuration is most economical, engineers and planners survey the local market for petroleum products and assess the available raw materials.

LOUISIANA CRUDE OIL REFINERY SURVEY REPORT

publication. The data used to construct the charts and graphs on oil production, refinery margins, and crude oil sources is obtained from DNR’s database. The time period covered by DNR’s current report is January 1, 2019 December 31, 2019 and is designed to complement the petroleum statistics published by the Energy Information

Permits, progress, and what Davis Oil & Gas Journal

Jul 16, 2018· However, in North Dakota you cannot build a refinery that is designed to, or capable of processing 50,000 b/d or more of crude oil unless you first obtain a siting certificate from the North

Worldwide Pipeline Construction: Crude Oil & Gas Journal

Feb 04, 2013· As 2013 began, operators had announced plans to build more than 44,800 miles of crude oil, product, and natural gas pipelines extending into the next decade, a 1.7% decrease from data reported the

Water Requirements of the Petroleum Refining Industry

A skimming or topping refinery separates crude oil by distillation into gasoline, kerosene, fuel oil, gas oil, and reduced crude. Atmos pheric distillation is generally the first step in refining crude oil. The crude oil is generally warmed by heat exchange with a fluid to be cooled. The use of the crude oil as a cooling medium reduces the

API Refinery Processes

Crude oil refineries employ some of the United States’ top scientists, engineers, and safety professionals to ensure that products are produced efficiently and safely. US refineries process about 17 million barrels of crude oil a day. Refinery configurations vary, but US refineries are undeniably some of the world’s most sophisticated

OIL REFINING & PROCESSING from Early, Mid to YouTube

FACTORIO MASTER CLASSThis series of Tutorials and How To Guides help you become a better Factorio EngineerEach video serves as a beginner's guide but also co...

Crude Oil Refinery Proposed Next To Theodore Roosevelt

Apr 17, 2016· While falling oil prices have slowed production from North Dakota's oil and natural gas fields, a company sees that lull as the perfect opportunity to build a crude oil refinery in the state. However, its proposed location just three miles from Theodore Roosevelt National Park has raised concerns from the National Park Service and conservation groups about how it will

Dung Quat, Oil Refinery No.1 Hydrocarbons Technology

The refinery is currently refining sweet crude oil produced in South East Asia. Following the completion of the expansion, the refinery will process 50% of Middle East sour crude oil and 50% of sweet crude oil. The expansion project will add a crude pre-flasher, vacuum distillation unit, a visbreaker, mercury removal unit and other facilities.

AN INTRODUCTION TO PETROLEUM REFINING AND THE

Assessing the refining value of a crude oil requires a full description of the crude oil and its components, involving scores of properties. However, two properties are especially useful for quickly classifying and comparing crude oils: API gravity (a measure of density) and sulfur content. 3.2.1 API Gravity (Density)

Private Owner Namibe Oil Refinery Angola Project

The project involves the construction of a refinery, a production unit, a drinking and waste water treatment plant, a power plant, a processing unit, a raw oil warehouse, a transport area, and a residential area for employees and the installation of accessories. The project is planned for development in phases.

REFINERY NEWS ROUNDUP: Some works end in Africa, but some

Dec 13, 2021· ** Ghana's sole oil refinery, Tema, remains offline and the plant is unlikely to restart for a few more months due to a lack of crude and feedstock. The plant has been hit by several issues over the past few years, experiencing intermittent outages at its crude distillation unit and FCC unit.

Crude Oil How Oil Refining Works HowStuffWorks

Crude oil is the term for "unprocessed" oil, the stuff that comes out of the ground. It is also known as petroleum.Crude oil is a fossil fuel, meaning that it was made naturally from decaying plants and animals living in ancient seas millions of years ago -- most places you can find crude oil were once sea beds.Crude oils vary in color, from clear to tar-black, and in viscosity, from water

Oil Refinery Dyson Sphere Program Wiki Fandom

Overview []. Refining facility, or the oil refinery is a building used for refining Crude Oil into Refined oil press equipment and Hydrogen.When researched, a second recipe is available for use in the refinery, X-Ray Cracking, which turns Refined Oil to Hydrogen and Energetic Graphite.The refinery is essential for any products that use Plastic as a component. In the early game it is the only way

A review of refinery complexity applications SpringerLink

Jan 04, 2017· A refinery is an industrial plant where crude oil and other feedstocks are processed into petroleum products. The main principle of refining is to separate and improve the hydrocarbon compounds that constitute crude oil to produce saleable products which satisfy regulatory requirements.

Transforming South Texas' Midstream Hart Energy

Sep 01, 2011· Plains All American Pipeline LP announced that it has entered into a commitment to construct a new 130-mile crude oil and condensate pipeline from the western portion of the Eagle Ford play and a marine terminal facility in Corpus Christi with 1.5 million barrels of storage capacity. Chesapeake Energy Marketing Inc. will be the anchor shipper

Refineries sprout in North Dakota Student News Daily

Apr 11, 2013· Still, with North Dakota diesel prices around $4.50 per gallon, a local supply of abundant Bakken oil that is roughly 4 percent cheaper than benchmark crude, and rising demand, diesel refining is a tempting proposition. It’s not clear how much cheaper locally produced diesel would be, as prices can vary depending on location, weather and access.

REVISION CARDS CRUDE OIL TO PLASTICS

Oil reserves are extracted by oil rigs on land and on the oceans / seas. On land, ‘crude oil’ is piped directly to refineries. Huge oil tankers often transport crude oil from oil rigs at sea, to refineries. Crude oil is a valuable commodity, as it can be refined (distilled) into fuels, chemicals and processed into plastics.

Hope for Nigeria Why private, greenfield refineries, can’t

Mar 17, 2016· According to him, modular refineries are capable of handling refining capacity of between 10,000 and 35,000 barrels of crude oil per day. On the private refineries, The Guardian gathered that the 39 projects with capacity to process 2.2 million bpd paid a non-refundable fee of $ 1 million each to DPR before licences were issued to them to build

Kalundborg Refinery

The oldest parts of the refinery started operations in 1961, and the plant has gradually been developed since. In 1995 a condensate destillation plant was added enabling the refinery to receive large volumes of condensates (light crude oil), which has improved our ability to produce high value products.

Oil refinery Official Factorio Wiki

The Oil Refinery processes crude oil into 3 different fluids: heavy oil, light oil and petroleum gas.. Oil products have many uses. Although they can be turned into solid fuel to fuel boilers and furnaces, they are usually used to create plastic bars, which are used in advanced circuits, and sulfur, which is used in more advanced items.They are also used as ammunition for

Post navigation