main chemicals and utility used for refining soya bean crude oil

Step by Step Soybean Oil Refining Process - Hope My Worlds

This is the first step of the soybean oil refining process. The collected crude oil contains a lot of dirt, impurities, and several types of gums, which are mainly phosphatides. These impurities are removed firstly in the degumming section of refining. There are three types of degumming processes used in this section.

Soybean Oil Refinery Plant Manufacturer & Exporter - Goyum India

Degumming. This is first step of soya bean oil refining where all the phosphatides will be removed. This will be taken into two steps. Step 1 mixing with hot water at 65 to 70°C allowing to react and gums will be separated with centrifuses, heavy phase will be gums and light phase will be de gummed oil.

Profitability Analysis of Soybean Oil Processes

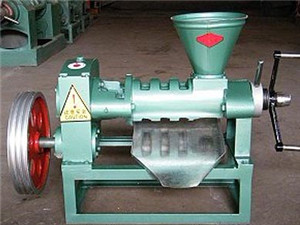

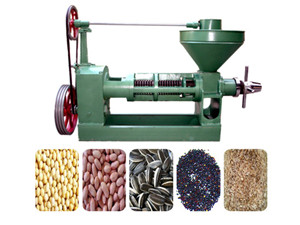

In the soybean refining process, extracting oil and concentrating protein contents are the two main purposes. The oil extraction is seen as the first step of soybean applications. The mechanical pressing technique, using pressure and heat to disrupt oleosome structure, was first used in the industry in the early 1940s . However, low oil yield, oil darkening, and oil deterioration resulted from over-heating are the major disadvantages of mechanical pressing process.

Refining of Roundup Ready (R) soya bean oil: Effect on the

The relative ratios of α-, β -, γ- and δ-tocopherols in crude oil, degummed oil, refined oil, bleached oil and deodorized soybean oil were almost constant, γ- and δ -tocopherols represented

Modelling and Analysis of a Soybean Biorefinery for the

To make soybean refined oil, crude oil must be refined, a purification process which encompasses 4 steps: degumming, neutralizing, bleaching and deodorizing. Figure 2 shows the oil refining process. The refining process starts with degumming, in which the phospholipids (gums) are removed from the oil stream by the addition of water.

Sunflower Mustard Soybean Biorefinery: Process Simulation and Analysis

Crude, degummed soybean oil was specified as the feedstock. Annual production capacity of the plant was set at 37,854,118 l (10 x 10(6)gal). Facility construction costs were calculated to be US

Cost Estimates for Soybean Processing and Soybean Oil Refining

The comparable operating expenses for a soybean oil refinery will average about $39.70 U. S. per metric ton of refined product ($35.30 to $48.50 range) with an incremental $22.00 U.S per metric ton for hydrogenated products ($17.60 to $38.50 range).

Introduction to Chemical Refining | Oil Palm Knowledge Base

The main purpose of chemical refining is to saponify the FFA by an alkaline solution and dilute the resulting soaps in a water phase. These soaps are removed by separators. The neutral oils are subsequently bleached and deodorised. This chemical refining can be used for reliably refining virtually all crude oils, including oils of low quality

Oil Refining - an overview | ScienceDirect Topics

The phospholipid separated from the crude oil is also called lecithin, which is a useful additive for food and animal feed. The temperature of the warm water needs to be the same as the oil temperature to avoid emulsion formation. The amount of warm water added to the crude oil is usually about 75% of the phospholipid content.

production and utility equipment in the oil refinery – edible

Oct 23, 2018 . The main products produced from oil refinery are naphtha oil, gasoline (gasoline), diesel fuel, kerosene, and LPG. . its basis, and on the basis of innovative proprietary design oil refining equipment. . Token type: utility token. Get Price

Optimization Model for the Integration of Biomass into a

main cases were analyzed in this study: Base Refinery, Case II: Ethanol and Biodiesel Blending, and Case III: Direct Biomass Integration. Upon thorough analysis of direct biomass integration options into the refinery model, the use of bagasse in producing pyrolysis oil was best suited for the study as the properties of pyrolysis oil is suitable for

Soybean Oil | Request PDF - ResearchGate

Soybean is used in making of, soybean oil, soy milk, tofu, tempeh, fermented bean paste, natto, soy sauce, soy flour, meat and dairy alternatives, soynut butter, vodka and other many products

Decanted Oil - an overview | ScienceDirect Topics

Ethylene is the main compound, leading to more than 40% of the final dry gas yield, and ethane and methane production is always close to 30% for both compounds. On the other hand, LPG production in the case of PO cracking is a very important fraction with a yield of ca. 25% under the tested reaction conditions ( Melero et al., 2010b ).

Lecithin production and utilization | SpringerLink

Lecithin is also used in numerous industrial and nonfood applications such as pigment dispersing, mold release, and animal feeds. The major source of commercial lecithin is from the processing of soybean oil. Evaluation of lecithins from other seed crops such as cotton, corn, and rapeseed is being pursued.

Oil Palm Knowledge Base | Anything and Everything About Oil Palm

Soybean oil and fatty acid additions are used to control acetone-insoluble matter, acid value, and viscosity. Lecithin can be chemically bleached with hydrogen peroxide, either before or after drying, to control the colour. The National Soybean Processors Association rules define six common grades of lecithin.

Sunflower Mustard Removal of phosphorus and iron by- ResearchGate

A crude soybean oil (5.7% free fatty acid) commercially extracted from damaged soybeans was degummed in the laboratory with different reagents: water, phosphoric acid, and acetic anhydride.

ASSESSING THE FEASIBILITY OF- Iowa State University

caustic soda and phosphoric acid to refine the crude oil. Consequently, interest has developed in creating a technology that allows “physical” refining of soybean oil. Unlike conventional refining that uses caustic soda to remove free fatty acids from the crude oil, physical refining relies on evaporation (a physical process) to

togo soybean crude oil refining plant in indonesia

Soyabean Oil Refinery Plant, Soyabean Oil RefinerySoyabean oilseeds are crushed into flakes and crude soya oil is extracted through the extraction machine system. The resulting product is crude soybean oil. This crude oil requires degumming to remove the gums from the Soyabean oil. The caustic material removes free fatty acids from the oil. The oil is bleached and deodorized subsequently. Get Price; Suppliers/soya Crude Oil Press Exporters, Suppliersour company is offering the bonny

Refining Plant Biomass: Biofuels, Green Chemistry | Planète

This pathway is used for crops such as rapeseed, sunflower, soybean and oil palm. The oils are first extracted before undergoing a chemical reaction known as esterification. The resulting biodiesel can be blended with regular diesel Diesel is the name of an internal combustion engine that works by compression-ignition.... A marketable byproduct of rapeseed and soybean conversion is the press cake, which can be used as animal feed.

Palm oil press equipment and Palm Kernel Oil Refining and Fractionation

The physical refining process can offer important advantages such as better oil yield, reduction of use of chemicals (phosphoric acid, citric acid, caustic soda, and sulfuric acid), reduction of water and effluent, and considerable reduction of the environmental impact; unfortunately, bleaching earth consumption is usually higher.

autocad physical refinery of edible oil

Two processes have been developed for the refining of edible oils and fats, i.e. physical and chemical refining; the decision which process to use depends on the types and qualities of the crude oil to be processed (Figure 1).The names physical and chemical refining come from the process technology used to remove the Free Fatty Acids (FFA) that

Continuous refining process. Medical search. fully automatic peanut oil press,groundnut oil processing machine,factory supplier edible oil expeller

Petrochemical Distillation Plant Deodorization Refineries Decoloring Process Batch Company has absorbed the advanced Hydrocarbon Alkali Semi-continuous Equipment Extraction Crude oil refinery Soybean oil Machine Catalysts Equipments Automatic Rice Type Iterative Temperature Turnkey Improvement Quality Oils Capacity Engineer Waste Examine

Title: -PROJECT PROPOSAL ON EDIBLE OIL- Academia.edu

Niger Seed: - Recovering rate of Niger seed crude oil to refined oil under the technology to be used (press solvent extraction method) results in 97% will be refined oil. The res 3% is refiner loss. Cotton Seed: - By the same token, the conversion rate of crude oil to refined oil per a given quantity of cotton crude oil is about 99%.

Edible Oil Refining Processes - Degumming / Neutralization

Miscella Refining What is Refining? The crude oil obtained either from expellers or solvent extraction plant contains impurities, which must be removed to make the oil edible, more palatable and stable against rancidity upon storage. The process of removing these impurities is called refining. Impurities present in the Oil. Gums: Gums are phospholipids. There are two types of gums present, hydratable and non-hydratable.

Glycerin and the market - UTC Scholar

2.1 Molecular Structure of Fat and Oil 7 2.2 Palmitic Acid (a) and Linoleic Acid (b) 9 2.3 Hydrolysis Reaction 12 3.1 Glycerin Production Processes and Product Compositions 14 3.2 Transesterification reaction 15 3.3 Esterification Reaction 16

Vegetable Oil Refinery Plant, Palm Oil Refinery Machinery

Physical Continuous Type Edible Oil Refinery Plant. Unlike batch oil refining process in which oil is processed in measured batch, in Continuous Vegetable Oil Refinery, crude oil is processed continuously with a constant stream of flow During the process, necessary chemicals and other utility items added

China High Cost-Effective Profitable Biodiesel Machine for

China High Cost-Effective Profitable Biodiesel Machine for Processing Crude Soya Bean Oil to Biodiesel, Find details about China Glycerol Plant, Glycerol Refining Equipment from High Cost-Effective Profitable Biodiesel Machine for Processing Crude Soya Bean Oil to Biodiesel - ,automatic palm kernel oil extraction machine and palm oil refinery machine plant.

Crude oil refining process. Medical search. fully automatic peanut oil press,groundnut oil processing machine,factory supplier edible oil expeller

Petroleum Fuel Oils Plant Oils Oils Hydrocarbons Oils, Volatile Alkanes Fish Oils Water Pollutants, Chemical Corn Oil Soybean Oil Polycyclic Hydrocarbons, Aromatic Mineral Oil Soil Pollutants Silicone Oils RNA, Ribosomal, 16S Safflower Oil Sulfur Sesame Oil Linseed Oil Gasoline Iodized Oil Castor Oil DNA, Ribosomal Benzene Alkenes Methanol DNA

2016 edible oil refinery. Medical search. fully automatic peanut oil press,groundnut oil processing machine,factory supplier edible oil expeller

Chemicals and Drugs 27 Petroleum Fuel Oils Plant Oils Oils Silicates Oils, Volatile Fish Oils Industrial Waste Corn Oil Soybean Oil Nickel Hydrocarbons Mineral Oil Gasoline Benzene Waste Water Aluminum Oxide Air Pollutants, Occupational Silicone Oils Dust Air Pollutants Sulfur Dioxide Safflower Oil Sesame Oil Linseed Oil Iodized Oil Castor Oil

Post navigation